Water-in-Oil EZ™ (Cetyl PEG/PPG-10/1 Dimethicone)

- Product Code: 726

Easily combines water with oil in a water-in-oil format, giving the serum a soft, smooth texture. Coat the surface well. This is the highlight of the water-in-oil serum which can be formulated with electrolyte freely. Does not cause the formula to soften or cause separation.

Type Medium Molecular Weight

Easily combines water with oil in a water-in-oil format, giving the serum a soft, smooth texture. Coat the surface well. This is the highlight of the water-in-oil serum which can be formulated with electrolyte freely. Does not cause the formula to soften or cause separation.

Type Medium Molecular Weight

Water-in-Oil EZ™ is a Cetyl PEG/PPG-10/1 Dimethicone type of medium molecular weight that easily binds water to oil in a water-in-oil form, giving the serum a soft, smooth texture. Coat the surface well. which is the highlight of the water-in-oil serum/cream texture, which can be freely formulated with electrolyte. Does not cause the formula to soften or cause separation.

Difference between Water-in-Oil EX™ and Water-in-Oil EZ™

An important factor that affects the efficiency of the emulsifier is the molecular weight of the polymers that are joined together. If the emulsifier has a larger molecular weight, it will have better cementation efficiency.

Water-in-Oil EX™ has a molecular weight that is at least 2 times larger than Water-in-Oil EZ™ , making it possible to cement formulas that are difficult to cement, such as having a high proportion of oil, a small proportion of water, etc.

In general formulas, it is recommended to use Water-in-Oil EZ™ which is cheaper. But if it is found that it cannot be coordinated or have stability problems Consider using Water-in-Oil EZ™.

Examples of popular products using Water-in-Oil EZ™:

- Concealer / Balm / Foundation / Cushion (oil part: Water-in-Oil EZ ™ + Wax + Oil/Silicone 30-35%, water 65-70%)

- Sun Screen (Oil: Water-in-Oil EZ ™ + Sun Screen/ Oil/Silicone 30-35%, Water 65-70%)

- Cream / Serum to nourish dry skin (oil part: Water-in-Oil EZ ™ + Oil/Silicone 20-35%, water part 65-80%)

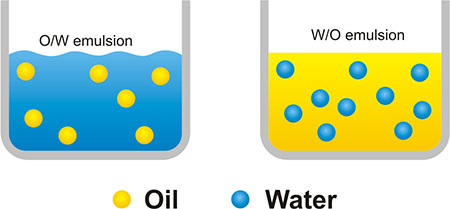

Description of water-in-oil emulsion (water wrapped in oil)

Usually, creams or gels for skin care are made from oil-in-water emulsion or encapsulating oil with water.

The picture on the left is oil-in-water emulsion. The picture on the right is water-in-oil emulsion.

The highlight of oil-in-water emulsion, which is used to make cream or gel to nourish the skin in more than 95% of all products, is that it is not greasy on the skin and is easily absorbed, while the disadvantage is that Cannot coat the skin well Due to the nature of the product being coated with water. When applied to the skin It will give the impression that water has been coated on the skin. Moreover, it is not waterproof. Because the formula is coated with water, once it comes in contact with water, it is washed away immediately. It is also not suitable for make-up formulas such as BB Cream, as it cannot spread pigments and foundations evenly on the skin. This is because pigments tend to dissolve in oil. When in an oil-in-water base, it cannot spread well both in the formula and on the skin.

The highlight of water-in-oil emulsion is that it can coat the surface well. Suitable for dehydrated, severely dry skin that needs to be coated so that the skin does not easily lose water. Ideal for use as a night cream, night serum, or for skin care in dry, cool weather or in air-conditioned rooms. In addition, an important highlight of water-in-oil is its water-repellent ability. and durability on the skin This is because the formula is coated with oil. Therefore it is durable on the skin for a long time. and can be waterproof well Therefore, it is suitable for both make-up and sun protection formulas. which requires durability and covers (spreads easily and evenly) on the skin

Additional instructions for use:

-The thickness of the formula depends on the amount of water in the formula. If there is more water, the formula will be thicker.

-Should not contain more than 5% each of Cyclomethicone, Dimethicone, Ethyl Alcohol, Propylene Glycol, Butylene Glycol, Glycerin in formulas using Water-in-Oil EZ™ as they can cause separation.

Difference between Water-in-Oil EZ™ and Water-Capsule™

Both Water-Capsule™ and Water-in-Oil EZ™ are used to create cream or serum formulas that have the same water-in-oil characteristics, but have the following differences:

- Water-in-Oil EZ™ Can work well in formulas containing electrolytes. without any impact Examples of substances with a high electrolyte content include DMAE , Sodium Lactate , while other binders include Water-Capsule™. Unable to create flesh or must be used in very high quantities

- Water-in-Oil EZ™ can hold up to 35% of oil, silicone, but Water-Capsule™ Can hold up to 20% oil if the formula emphasizes the use of silicone or has a high proportion of oil. Please use Water-in-Oil EZ™.

- Water-Capsule™ You can easily get the formula to be thick-liquid by blending harder/for a longer time. You will get a thicker formula, but to adjust the thickness of Water-in-Oil EZ™ you will need to adjust the mixing ratio or use Gel Maker / Thickener to help.

Important - Mixing steps

Mixing must include water. Add it to the oil portion. By adding a little bit at a time and blending or stirring continuously. If vice versa, take the oil part. Add it to the water. It will take a lot longer to stir or blend. Or maybe they don't match at all.

Detailed steps:

1. Mix Water-in-Oil EZ™ into the oil portion. (Any type of oil such as Isododecane, Mineral Oil, Jojoba Oil) Stir or blend until smooth.

2. Prepare the water by mixing water with any ingredients that dissolve in water.

3. Take the water part. Add it to the oil portion. By gradually adding little by little and the poor are one flesh Then continue adding in Do not fill it all in at once. This is because it takes a very long time to blend or stir until you get the formula.

Please see the video example showing how to mix. https://www.youtube.com/watch?v=u8GGITnUqx4

*If the formula has a lot of water The formula will be thick. If the formula contains a lot of oil or silicone The formula will be liquid. It is recommended that the proportion of oil + silicone be at the level of 20-35% if using heavy oil. Please reduce the proportion of oil*

*If the formula contains more than 35% oil, please consider using Oil-Fix™ to help increase stability. Prevents layer separation*

Example of DMAE Light Serum formula

Isododecane 20%

DMAE (SkinTight MD™) Liquid 20%

Water 57.5%

Phenoxyethanol 0.5%

Water-in-Oil EZ™ 2%

Sodium Lactate Ultra-Moisturizing Serum formula example

Mineral Oil (Paraffinum Liquidum) light type 15%

Water 76.5%

Phenoxyethanol 0.5%

Water-in-Oil EZ™ 2%

Adjusting the thickness of the formula using Water-in-Oil EZ™ to bind and create texture.

Can be done in 3 ways

1. Add approximately the same proportion of water. (and reduce the proportion of oil)

2. Add water-soluble Thickener such as Xanthan Gum to the water and blend to get a gel texture first. Adjust the thickness more or less as desired Then follow other steps as usual. The thicker part of the water It will make the formula thicker. Please see an example of thickening the meat with Xanthan Gum according to the recipe below.

3. Add an oil-soluble Thickener such as Hectorite Gel to the oil portion. Blend until combined with the oil mixture.

4. Add Wax to the oil part.

For formulas that are Water in Oil (contains both water and oil, using Water-in-Oil EZ™ to coordinate the formula), it is recommended to add 1% Magnesium Sulfate to help increase the stability of the formula. Reduce the chance of class separation

Usage: As a binder for water and oil and silicone, can be used in all formulas.

How to mix: Mix in oil well. Then the water is gradually added to the oil. Please read further details above, the formula should include 1% Magnesium Sulfate to help increase the stability of the Water-in-Oil Emulsion.

Usage rate: 0.1-4% (1-2% recommended for most formulas)

Product characteristics: Clear, thick, light yellow liquid.

Solubility: Can be dissolved in oil.

Storage: Can be stored at room temperature. But close the bottle cap tightly. Then completely protected from sunlight or heat.

INCI Name : Cetyl PEG/PPG-10/1 Dimethicone

Example of a product that uses Cetyl PEG/PPG-10/1 Dimethicone to create the formula.

MiSSHA All Around Safe Block Soft Finish Sun Milk SPF50

NYX Stay Matte But Not Flat Liquid Foundation

CLINIQUE Mineral Sunscreen Lotion For Body SPF30

KIEHL'S 10.5 Powerful-Strength Line-Reducing Concentrate

| Mechanism | - |

| Appearance | - |

| Longevity | - |

| Strength | - |

| Storage | - |

| Shelf Life | - |

| Allergen(s) | - |

| Dosage (Range) | - |

| Recommended Dosage | - |

| Dosage (Per Day) | - |

| Recommended Dosage (Per Day) | - |

| Mix Method | - |

| Heat Resistance | - |

| Stable in pH range | - |

| Solubility | - |

| Product Types | - |

| INCI | - |

Purchase History for

Cart

No products