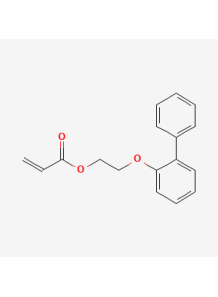

O-Phenylphenoxyethyl Acrylate (OPPEA)

- Product Code: 35714

significant application in UV-curable resin formulations due to its unique properties and reactivity

very high refractive index

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

| Test Name | Specification |

|---|---|

| Appearance | Transparent liquid |

| Acid value (mg KOH/g) | 0.5 Max |

| APHA | 100 Max |

| Viscosity at 25C (cps) | 100-200 |

| Density (g/mL, 25/4C) | 1.15 |

| Tg (C) | 30-35 |

| Refractive Index | 1.56-1.59 |

O-Phenylphenoxyethyl Acrylate (OPPEA) finds significant application in UV-curable resin formulations due to its unique properties and reactivity.

Reactive diluent: OPPEA is commonly used as a reactive diluent in UV-curable resin formulations. It helps to adjust the viscosity of the resin system, improving flow and application properties. Additionally, it contributes to the flexibility and adhesion of the cured resin.

Radiation-curable coatings and inks: UV-curable coatings and inks for various substrates, such as wood, plastics, and metals, often contain OPPEA as a reactive component. It imparts flexibility, chemical resistance, and adhesion to the cured coatings and inks.

Overprint varnishes: OPPEA is used in the formulation of UV-curable overprint varnishes, which are applied as a protective layer over printed materials. It enhances the flexibility, scratch resistance, and overall durability of the varnish.

Photoresists and printing plates: In the electronics and printing industries, OPPEA is incorporated into photoresist and printing plate formulations, where it contributes to the sensitivity, resolution, and physical properties of the cured resins.

Adhesives and sealants: UV-curable adhesives and sealants often include OPPEA as a reactive component to improve flexibility, adhesion, and chemical resistance.

Be the first to review this product :-)

บริการวิเคราะห์

| บริการแลป | ราคา |

|---|

significant application in UV-curable resin formulations due to its unique properties and reactivity

very high refractive index

O-Phenylphenoxyethyl Acrylate (OPPEA) finds significant application in UV-curable resin formulations due to its unique properties and reactivity.

Reactive diluent: OPPEA is commonly used as a reactive diluent in UV-curable resin formulations. It helps to adjust the viscosity of the resin system, improving flow and application properties. Additionally, it contributes to the flexibility and adhesion of the cured resin.

Radiation-curable coatings and inks: UV-curable coatings and inks for various substrates, such as wood, plastics, and metals, often contain OPPEA as a reactive component. It imparts flexibility, chemical resistance, and adhesion to the cured coatings and inks.

Overprint varnishes: OPPEA is used in the formulation of UV-curable overprint varnishes, which are applied as a protective layer over printed materials. It enhances the flexibility, scratch resistance, and overall durability of the varnish.

Photoresists and printing plates: In the electronics and printing industries, OPPEA is incorporated into photoresist and printing plate formulations, where it contributes to the sensitivity, resolution, and physical properties of the cured resins.

Adhesives and sealants: UV-curable adhesives and sealants often include OPPEA as a reactive component to improve flexibility, adhesion, and chemical resistance.

| Mechanism | - |

| Appearance | - |

| Longevity | - |

| Strength | - |

| Storage | - |

| Shelf Life | - |

| Allergen(s) | - |

| Dosage (Range) | - |

| Recommended Dosage | - |

| Dosage (Per Day) | - |

| Recommended Dosage (Per Day) | - |

| Mix Method | - |

| Heat Resistance | - |

| Stable in pH range | - |

| Solubility | - |

| Product Types | - |

| INCI | - |

ตะกร้า

ไม่มีสินค้า