Methacrylic Acid - Methyl Methacrylate Copolymer (1:1) (e.q. Eudragit L100) (Powder)

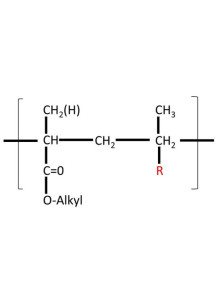

Methacrylic Acid - Methyl Methacrylate Copolymer (1:1) or popularly known as Eudragit L100 (products sold by the company Not produced by the manufacturer Eudragit)

It is a polymer commonly used to coat tablets for pharmaceutical applications. It is a type of acrylic polymer known as acrylic resin or acrylic copolymer. It has the following features:

Film Forming Properties: It has excellent film forming properties. This enables a continuous and uniform thin coating on the tablet surface. The resulting film helps prevent and control the release of active pharmaceutical ingredients (API).

Solubility independent of pH: one of its key advantages. is the solubility independent of pH, insoluble in both acidic and alkaline environments. Maintain integrity and function throughout the gastrointestinal tract This property makes it suitable for both instant release coating and intestinal coating.

Moisture and Oxygen Protection: Good moisture and oxygen protection. This protects the pill core from environmental factors that may affect drug stability and efficacy. This is especially useful for drugs that are moisture sensitive or oxygen sensitive.

Taste Masking: It can be used to mask the unpleasant taste or smell of some medications. Polymers form a barrier between the taste buds or smell and the taste buds in the mouth. Reduces sensory impact

Customizable drug release profiles: by adjusting the coating thickness and the ratio of MA to MMA in the copolymer. Drug release profiles are customizable. This allows the development of modified release formulations, such as extended-release tablets. delayed release or pulsatile

Compatibility and security: In general It is considered safe for medicinal use. Compatible with a wide range of APIs and excipients commonly used in tablet formulations. It has been approved by regulators such as the US Food and Drug Administration (FDA) for oral use.