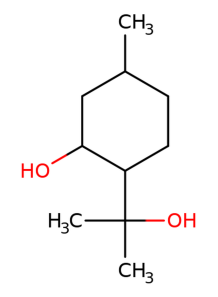

p-menthane-3,8-diol (PMD) is a plant-derived/synthetic insect-repellent active most commonly associated with oil of lemon eucalyptus (OLE).

In finished products, PMD is used in skin-applied repellents to reduce mosquito landings/bites and support tick-bite prevention. It repels (it does not “kill” insects).

PMD can be very effective, but real-world duration is typically more variable than DEET or picaridin and depends strongly on PMD concentration, formulation design, and mosquito pressure (heat, sweat, swimming, or rubbing skin can shorten protection time).

Also known as

- PMD (para-menthane-3,8-diol)

- Menthanediol (INCI)

- “Citriodiol” (common trade term)

Product Description: Repellent performance is commonly reported using two complementary endpoints:

- % repellency: reduction in bites/landings versus an untreated control

- Complete Protection Time (CPT): time until the first confirmed bite/landing in a defined test setup

Across field and laboratory studies, PMD often provides multi-hour protection, but tends to show greater variability than long-used benchmarks like DEET/picaridin. Higher active concentration and a well-designed carrier system generally extend duration; very low concentrations can fall to short protection windows under heavy mosquito pressure.

| Model/System |

Typical Reported Results |

Implication |

| Field studies (high mosquito pressure) |

Often several hours CPT; repellency commonly reported ~high‑80s to ~90%+ |

Plan on reapplication; duration depends on environment and formulation |

| Comparative testing versus DEET |

PMD can approach DEET in some settings, but averages often shorter |

Good non‑DEET option; reliability improves with higher % active |

| Real‑world modifiers |

Sweat, swimming, wiping skin, and heat shorten protection time |

Choose robust carriers/solubilizers; reapply sooner in harsh conditions |

Safety / regulatory note: PMD is used in registered repellent products in several markets. Follow local regulations and finished-product labeling requirements. Avoid eyes/mouth; do not apply to broken skin; and many public health guidances advise avoiding OLE/PMD use on children under 3 years old.

Usage: Skin-applied insect repellent products (sprays, lotions, creams, roll-ons) targeting mosquito and tick bite prevention.

Mixing method:

- Add into the oil phase or solvent phase (PMD is oil/solvent soluble).

- For clear hydroalcoholic or glycol systems: pre-dissolve in ethanol or glycols before adding to the bulk.

- For water-based sprays: use a suitable solubilizer/emulsifier system to prevent separation and maintain clarity.

- Avoid prolonged high temperature; add during cool-down when possible to reduce evaporation and odor loss.

Usage rate: 10–40%

This material is typically supplied as high-assay PMD (>95%). Using 10–40% of this ingredient delivers approximately ~9.5–38% PMD in the finished formula (delivered-active depends on assay and total formula).

Product characteristics: Colorless to light yellow liquid or waxy crystals (temperature-dependent); mild characteristic odor.

Solubility: Insoluble in water; soluble in oils, glycols, and ethanol. Use solubilizers/emulsifiers for stable water-based systems.

Storage: Store cool (refrigerated when possible). If crystallization occurs at low temperature, warm gently and mix until uniform.