a type of polyisocyanate hardener used primarily in the formulation of polyurethane coatings, adhesives, and sealants. It is a product from Covestro, a leading producer of high-performance polymers and materials

Desmodur L75 is a type of aromatic polyisocyanate used primarily in the formulation of polyurethane coatings, adhesives, and sealants. It is a product of Covestro, a company known for its high-performance polymers and materials. Desmodur L75 is known for its reactivity and performance characteristics, especially in coatings applications.

Key Characteristics

-

Chemical Composition:

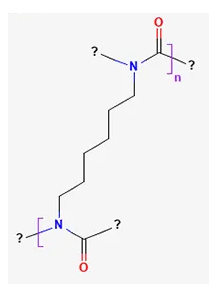

- Type: Aromatic polyisocyanate based on toluene diisocyanate (TDI).

- Isocyanate Content: Typically around 13.0-14.0% by weight.

- Viscosity: Approximately 3,000-6,000 mPa·s at 23°C.

-

Properties:

- Reactivity: Highly reactive, making it suitable for fast-curing applications.

- Mechanical Properties: Provides coatings with good hardness and flexibility.

- Durability: Offers good protection and performance in a variety of environments.

Applications

-

Coatings:

- Industrial Coatings: Suitable for use in industrial environments where quick drying and robust performance are required.

- Wood Coatings: Provides a durable finish for wood surfaces, enhancing resistance to abrasion and chemicals.

- Protective Coatings: Used in coatings that need to withstand harsh conditions, such as floor coatings and heavy-duty maintenance coatings.

-

Adhesives and Sealants:

- Construction Adhesives: Used in bonding applications requiring strong adhesion and quick curing.

- Sealants: Provides effective sealing solutions with good mechanical properties and resistance.

Advantages

- Fast Curing: High reactivity allows for quick drying and curing, which is beneficial in time-sensitive applications.

- Durability: Offers good mechanical strength and resistance to environmental factors.

- Versatility: Can be used in a wide range of formulations and applications.

Disadvantages

- Aromatic Nature: Being based on TDI, it may have higher sensitivity to UV light, leading to potential yellowing or degradation when exposed to sunlight over time.

- Handling Requirements: Requires careful handling and safety precautions due to the reactive nature of isocyanates.

Handling and Safety

-

Personal Protective Equipment (PPE):

- Use appropriate PPE, including gloves, goggles, and protective clothing, to prevent skin and eye contact.

- Ensure the use of respirators or adequate ventilation to avoid inhalation of vapors.

-

Storage:

- Store in tightly closed containers in a cool, dry place away from moisture and sources of ignition.

- Protect from temperatures below 10°C and above 30°C to maintain product stability.

-

Safety Measures:

- Follow all safety data sheet (SDS) recommendations for safe handling and disposal.

- Use in well-ventilated areas to prevent the buildup of vapors.