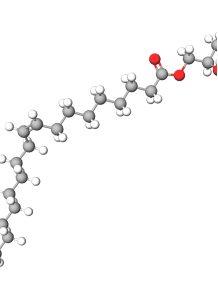

Cholesteryl Oleate is a cholesteryl ester: the hydroxyl group of cholesterol is esterified with oleic acid (C18:1, cis‑9), yielding a very non‑polar, waxy lipid with strong affinity for oil phases.

This ingredient is widely used in many La Prairie and KOSE product lines as part of the oil‑phase “sensory engineering” toolset to build a richer, more cushiony lipid film and a more premium afterfeel.

Because it has no strong hydrophilic headgroup, Cholesteryl Oleate is not a classical HLB surfactant and will not emulsify on its own; in formulas it functions primarily as an oil‑phase structurant, sensorial modifier, and lipid film former.

Product Description: Cholesteryl Oleate (CAS 303‑43‑5; C45H78O2; MW 651.10) is typically supplied as a white to off‑white waxy solid/powder with a melting range around 44–47°C. In skin‑lipid terms, cholesteryl esters such as cholesteryl oleate occur in sebum (often denoted CE 18:1) and are best positioned as “surface‑lipid / sebum‑mimetic” components that influence film properties and sensory comfort.

A practical formulation nuance is that cholesteryl oleate is not a drop‑in substitute for free cholesterol in stratum‑corneum lamellar barrier‑lipid models; it can phase‑separate in SC‑type matrices. Therefore, it is typically used to complement (not replace) classical barrier‑lipid systems (ceramides + free cholesterol + fatty acids) by tuning the surface film, glide, and cushion.

- Oil‑phase structuring: behaves like a soft wax that increases oil‑phase viscosity and helps slow sedimentation of pigments, powders, UV filters, and other dispersed solids.

- Sensory modulation: increases cushion/richness and reduces “dryness” of volatile or low‑viscosity oils by leaving a more substantive lipid film.

- Film & payoff control: improves lubricity and payoff in anhydrous balms/sticks and in color cosmetics (binder feel and spread).

- Ordered phase potential: sterol esters can contribute to partial ordering/mesophase behavior that changes rheology and perceived substantivity (system‑dependent).

Usage: Moisturizers and barrier‑support creams (as a sensorial lipid), facial oils and oil‑based serums, body butters and balms, lip products, and oil/silicone hybrid color cosmetics; also useful in oil‑phase suspensions (pigments, UV filters).

Mixing method:

- Treat as an oil‑phase solid: pre‑melt and dissolve into the oil phase above its melting point (commonly ~50–70°C) before emulsification or before filling anhydrous products.

- To reduce graininess/bloom from recrystallization: avoid shock cooling, keep the level modest relative to total wax load, and include enough liquid oils/esters that remain fluid at low temperature.

- Not an emulsifier: for O/W systems, use a suitable emulsifier system; cholesteryl oleate mainly modifies the internal oil phase rheology and post‑apply film.

- Oxidation management: the oleate chain is monounsaturated; consider standard antioxidants (e.g., tocopherol blend) in rich lipid systems.

Usage rate: 0.1–5%

Delivered‑active note: this is a neat lipid ingredient (not a dilute concentrate), so the use level equals the delivered level in the finished formula. Typical sensorial tuning is often ~0.5–2% depending on the oil/wax network.

Product characteristics: White to off‑white waxy solid/powder; very oil‑affine; melts around 44–47°C.

Solubility: Insoluble in water; oil‑soluble (dissolves on heating in esters, hydrocarbons, triglyceride oils, and many organic solvents). Validate clarity and texture on cooling for each oil system.

Storage: Store tightly closed, protect from heat and direct light. Avoid prolonged high temperatures that can soften/melt the waxy matrix; use antioxidants as appropriate for lipid‑rich formulas.