Reactive Amine (Co-initiator, 2F, e.q. AgiSyn 008)

Reactive amines are commonly used in various industrial processes, including UV coating applications. UV coatings, also known as ultraviolet coatings

MW: 500 , Viscosity (25C) 800-1500mPa.s.

Reactive amines are commonly used in various industrial processes, including UV coating applications. UV coatings, also known as ultraviolet coatings, are a type of surface finish applied to various materials, such as wood, plastic, metal, and paper, to provide protection, enhance appearance, and improve durability. These coatings cure quickly when exposed to ultraviolet (UV) light, which triggers a photochemical reaction that transforms the liquid coating into a solid film.

Reactive amines play a role in UV coating formulations as crosslinking agents or co-reactants. Crosslinking is a process that involves chemically connecting individual polymer chains to create a more stable and durable network structure. In UV coatings, reactive amines can act as co-reactants with other reactive components like acrylates or epoxy resins. The amine groups in these compounds can participate in reactions with the acrylate or epoxy functional groups, resulting in the formation of crosslinked polymer networks. This crosslinking improves the coating's hardness, adhesion, chemical resistance, and overall performance.

Here's a simplified overview of how reactive amines function in UV coating systems:

Formulation: Reactive amines are incorporated into the UV coating formulation along with other ingredients like oligomers, monomers, photoinitiators, and additives.

Application:

The UV coating is applied to the substrate using methods such as spraying, dipping, or roller coating.

UV Exposure: The coated substrate is exposed to UV light with specific wavelengths using UV curing equipment. Photoinitiators in the formulation absorb UV light and generate free radicals or other reactive species.

Crosslinking: Reactive amines present in the formulation react with the generated free radicals or other reactive species. These reactions lead to the formation of covalent bonds between the polymer chains, creating a three-dimensional network structure.

Curing: As the crosslinking reactions progress, the liquid coating solidifies and forms a durable and chemically resistant film.

MW: 500

Viscosity (25C) 800-1500mPa.s.

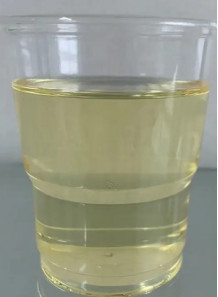

Color (Gardner) : 2 Max

Appearance : Yellowish transparent liquid