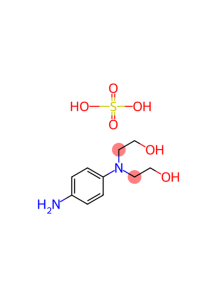

BHE‑PPD sulfate (NNBIS) (Oxidation Base / Primary)

Cart

No products

No products

BHE‑PPD sulfate (Oxidation Base / Primary) is a water‑soluble oxidative hair dye precursor ("primary intermediate" / oxidation base) designed for permanent oxidative hair colorant systems.

INCI (EU/SCCP): N,N‑bis(2‑hydroxyethyl)‑p‑phenylenediamine sulphate (CAS 54381‑16‑7; EC 259‑134‑5). Synonyms seen in regulatory dossiers include 2,2′‑[(4‑aminophenyl)imino]bis(ethanol) sulphate and Ethanol, 2,2′‑[(4‑aminophenyl)imino]bis‑, sulphate (1:1) (salt).

In an oxidative dye architecture, the final shade is governed by the coupler set and oxidation conditions (pH, peroxide strength, processing time, and hair substrate). This ingredient is typically formulated in Part A (dye base) and is activated after mixing with a peroxide developer (Part B).

Product Description: BHE‑PPD sulfate is a hydrophilic aromatic amine salt that behaves as a water‑phase dye intermediate. Its high water solubility makes it straightforward to pre‑dissolve and dose precisely, while its poor ethanol solubility means ethanol is not an effective primary carrier for meaningful loadings.

| Property | Typical dossier‑reported notes |

|---|---|

| Appearance | White to greyish powder |

| Solubility | Very high in water (~296 mg/mL reported); very low in ethanol (~0.23–0.35 mg/mL); high in DMSO (lab solvent) |

| Hydrophilicity | Calculated log Pow around −0.77 (free base), consistent with a strongly hydrophilic profile |

| Stability (practical) | Stable as a solid when stored protected from light; aqueous solutions have limited stability windows that improve with antioxidant systems |

Regulatory / design constraints (formulator view)

- EU Cosmetic Regulation Annex III (hair dye restriction): maximum on‑hair concentration is set on the ready‑to‑use mixture after mixing (reported as sulfate).

- Nitrosation controls typically apply: do not use with nitrosating agents; manage nitrosamines to a tight limit (e.g., 50 µg/kg) and use nitrite‑free containers/packaging.

- This means the allowable concentration in Part A depends on your developer ratio (B:A) and must be calculated to keep the mixed, ready‑to‑use product compliant.

For a 2‑part system (Part A dye base + Part B developer), the concentration relationship is:

- C_A = C_mix × (1 + R), where R is the developer‑to‑Part‑A weight ratio (B:A).

- Example: 1:1 mix → C_A is 2× the mixed concentration; 1:2 mix → C_A is 3× the mixed concentration.

| Mix ratio (B:A) | Multiplier (1+R) | Implication for Part A ceiling |

|---|---|---|

| 1:1 | 2.0× | Part A must be ≤ 2× the ready‑to‑use limit |

| 1:1.5 | 2.5× | Part A must be ≤ 2.5× the ready‑to‑use limit |

| 1:2 | 3.0× | Part A must be ≤ 3× the ready‑to‑use limit |

Solubilization & processing guidance

- Treat as a water‑phase dye: pre‑dissolve in DI water (optionally with polyols such as propylene glycol / ethoxydiglycol if your system uses them).

- Avoid relying on ethanol as the primary carrier (very low ethanol solubility at meaningful levels).

- Add dyes late in manufacturing where possible (cool‑down) to reduce time at elevated temperature and oxidative conditions.

- Minimize air entrainment (gentle sweep mixing; avoid vortexing) and fill with low headspace; use UV‑limiting/opaque packaging when feasible.

Stability controls (oxidative dye bases)

- Chelation: trace Fe/Cu accelerates oxidative darkening; use a chelator (e.g., EDTA) and low‑metal raw material grades.

- Antioxidant/reducing systems are commonly used to suppress premature oxidation in‑pack (examples include erythorbic/ascorbic acid and sulfite/bisulfite systems, validated per your formula and packaging).

- Avoid reactive botanicals/fragrances or inputs with high trace‑metal and reactive carbonyl loads unless screened for discoloration.

Nitrosamine risk (design‑out first, then verify)

- Do not formulate with nitrosating agents; treat nitrite as a critical contaminant (water quality, certain raw materials, recycled packaging risks).

- Specify nitrite‑free packaging and verify by supplier declarations plus periodic analytical checks as needed.

- Include nitrosamine testing in release and stability where required by your region and product category.

Compatibility watch‑outs

- Cationic polymers/conditioners: may haze or complex depending on pH/ionic strength; screen with your chosen polyquat systems.

- High electrolyte bases: as a sulfate salt, it increases ionic strength and may shift viscosity in salt‑sensitive thickeners.

QC & troubleshooting (practical)

- Identity/assay: HPLC assay is commonly used for oxidative intermediates (e.g., UV detection around 254 nm depending on method).

- Monitor: discoloration (ΔE), precipitation/haze on cycling, and shade drift after mixing (development curve) as stability indicators.

- Typical failure patterns:

- Base darkening over time → metal catalysis / insufficient antioxidant / oxygen ingress → strengthen chelation + antioxidant package; reduce air; improve barrier packaging.

- Precipitation → local supersaturation / solvent mismatch → fully pre‑dissolve in water; adjust polyol ratio; add at lower temperature; avoid ethanol carrier.

Usage: Permanent oxidative hair colorants (two‑part cream/gel systems), professional rinse‑off hair dye bases, and related oxidative dye applications where permitted by local regulations.

Mixing method:

- Pre‑dissolve in DI water (or water + compatible polyol) before adding to the dye base; ensure complete dissolution to avoid crystallization.

- Add during cool‑down (recommend <40°C) and mix gently to minimize air oxidation.

- Formulate with chelation and an appropriate antioxidant/reducing system; exclude nitrosating agents and control nitrite contamination; validate nitrosamines and regional compliance on the final ready‑to‑use mixture.

Usage rate: 0.1–5.0%

This range is typically expressed for Part A (dye base). Always calculate the ready‑to‑use (after‑mixing) concentration from your A:B ratio and comply with your region’s Annex III hair‑dye limits for this ingredient.

Product characteristics: White to greyish powder

Solubility: Highly soluble in water; very low solubility in ethanol; soluble in DMSO (lab solvent). Practical best practice is to treat this as a water‑phase dye intermediate.

Storage: Store tightly closed, dry, and protected from light. Minimize oxygen exposure and avoid contact with reactive metals; aqueous solutions should be stabilized and used within validated stability windows.

| Mechanism | - |

| Appearance | - |

| Longevity | - |

| Strength | - |

| Storage | - |

| Shelf Life | - |

| Allergen(s) | - |

| Dosage (Range) | - |

| Recommended Dosage | - |

| Dosage (Per Day) | - |

| Recommended Dosage (Per Day) | - |

| Mix Method | - |

| Heat Resistance | - |

| Stable in pH range | - |

| Solubility | - |

| Product Types | - |

| INCI | - |