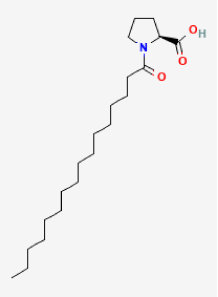

Palmitoyl Proline

Cart

No products

No products

Palmitoyl Proline is a lipo‑amino acid formed by coupling palmitic acid (a C16 fatty acid) to the amino acid proline. In cosmetic formulations it behaves as an amphiphilic skin‑ and hair‑conditioning agent that can sit at the interface between aqueous and lipid phases, supporting a soft, flexible film on the skin surface.

Within this lipo‑amino acid family, palmitoyl proline itself is mainly used as a helper for barrier comfort and texture, while closely related pseudoceramide derivatives (for example N‑palmitoyl‑4‑hydroxy‑L‑proline palmityl ester) have been shown in experimental models to repair a damaged stratum corneum with performance comparable to natural ceramides. Together these data support the use of palmitoyl‑proline chemistry as a lipid‑compatible conditioning scaffold in barrier‑supportive formulas.

Formulation work and manufacturer studies on palmitoyl proline and its sodium salt describe improvements in perceived hydration and comfort, attenuation of irritation‑related markers when used in soothing complexes, and more even tone in complexes that combine sodium palmitoyl proline with water‑lily extract. For the single molecule palmitoyl proline, evidence is strongest for moisturization, barrier comfort and sensory benefits; brightening effects are mainly associated with such multi‑component complexes rather than the neat raw material.

Typical use is at low levels (around 0.05–0.5% in the finished product) in moisturizers, serums, after‑sun and barrier‑repair concepts, as well as in pigmented systems (foundations, cushions, sunscreens) where its amphiphilic character helps wet pigments and gives a soft, velvety after‑feel.

Product Description: Chemically, palmitoyl proline is an N‑acylated amino acid: a C16 palmitoyl chain attached to proline. The palmitoyl tail anchors into lipid domains while the proline head group interacts with the aqueous environment, giving an amphiphilic molecule that can organize at interfaces, support a continuous lipid film and help reduce transepidermal water loss (TEWL). In emulsion systems it can contribute to a smoother, more elastic skin feel and improve the dispersion of pigments and inorganic UV filters.

In vitro work on palmitoyl‑proline pseudoceramides indicates that these structures insert into disrupted barrier lipid matrices and partially restore lamellar organization. A widely cited study on an N‑palmitoyl‑4‑hydroxy‑L‑proline palmityl ester reported barrier repair performance similar to natural ceramides in damaged‑skin models, with normalization of TEWL over time and improved recovery of stratum‑corneum integrity. While this particular pseudoceramide is not identical to pure palmitoyl proline, it reinforces the rationale for using palmitoyl‑proline chemistry in barrier‑supportive moisturizers.

For soothing effects, more data exist on sodium palmitoyl proline in combination with water‑lily extract: manufacturer cell‑culture studies on stressed keratinocytes report reductions in pro‑inflammatory mediators and improved tolerance in cosmetic use tests on sensitive or post‑procedure skin. Similar complexes have also been described as reducing the expression of tyrosinase and melanin‑related markers in melanocyte models, with small‑scale cosmetic clinicals reporting more even tone and lighter post‑inflammatory marks. These results should be interpreted as complex‑level effects; neat palmitoyl proline should be positioned primarily as a gentle conditioning, barrier‑comfort and texture‑optimizing component.

On the hair and scalp side, lipo‑amino acids including palmitoyl proline are used as conditioning agents that improve combability, reduce friction and help rebuild the lipid micro‑environment on the scalp in leave‑on lotions for dry, flaky or irritated scalps. Several pseudoceramide‑containing systems in this family have shown improvements in dryness, scaling and itch in conditions such as seborrhoeic dermatitis and atopic‑dermatitis‑prone skin, again supporting the broader concept of ceramide‑mimicking lipids for compromised barriers.

| Model/System | Key endpoints | Implication |

|---|---|---|

| Damaged‑skin barrier models with palmitoyl‑proline pseudoceramides | Recovery of TEWL, improved lipid‑lamellae organization vs. untreated | Supports barrier‑repair use |

| Keratinocyte models with sodium palmitoyl proline + water‑lily complexes | Reduced inflammatory mediators under chemical/UV stress | Soothing, anti‑discomfort positioning |

| Melanocyte/skin‑equivalent models with palmitoyl‑proline complexes | Reduced tyrosinase expression and melanin markers | Gentle tone‑evening in complexes (not neat raw) |

Usage: Low‑level conditioning and barrier‑supportive component for facial and body moisturizers, serums, milks, after‑sun and post‑procedure care, as well as make‑up and sunscreen systems where a soft, velvety feel and pigment wetting are desired. Can also be used in hair leave‑ons and scalp lotions targeting dryness, scaling and discomfort.

Mixing method:

- For emulsions (creams/lotions): Disperse palmitoyl proline into the oil phase or a suitable co‑solvent blend (for example light esters or cosmetic polyols), then emulsify as normal. For maximum comfort and color stability, post‑add part or all of the active during cool‑down below 40°C.

- For gels/serums: Pre‑solubilize in glycols or in a microemulsion base, then add to the aqueous gel at the final stage under good mixing. Use appropriate surfactant or polymeric solubilizer systems to keep the lipo‑amino acid uniformly dispersed.

- General: Avoid prolonged heating and very high pH; design systems to keep the finished product in the approximate pH 4.0–7.5 window and add the active as late as practical in the process.

Usage rate: 0.05–0.5% in the finished formula (typical 0.1–0.3% in leave‑on facial products; use toward the lower end in sensitive‑skin or post‑procedure concepts and increase only after in‑house tolerance data are available).

Product characteristics: White to off‑white powder; practically odourless; amphiphilic lipo‑amino acid (palmitic acid + proline).

Solubility: Sparingly soluble in water; soluble in cosmetic polyols (for example propylene/butylene glycol) and many emollient oils; readily incorporated into surfactant systems and emulsions when pre‑dispersed or pre‑solubilized.

For use by experienced formulators only; not a finished cosmetic product.

| Mechanism | - |

| Appearance | - |

| Longevity | - |

| Strength | - |

| Storage | - |

| Shelf Life | - |

| Allergen(s) | - |

| Dosage (Range) | - |

| Recommended Dosage | - |

| Dosage (Per Day) | - |

| Recommended Dosage (Per Day) | - |

| Mix Method | - |

| Heat Resistance | - |

| Stable in pH range | - |

| Solubility | - |

| Product Types | - |

| INCI | - |