Myristic Acid (FEMA-2764)

Myristic Acid 99%

Cart

No products

No products

Myristic Acid 99%

Myristic Acid 99%

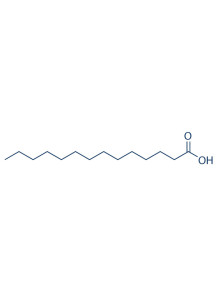

Myristic acid (tetradecanoic acid) is a 14-carbon, saturated fatty acid commonly derived from coconut oil, palm kernel oil, or animal fats. In cosmetic formulations, it serves multiple roles—chiefly as an emollient, thickening agent, and precursor to surfactants. Its solid, waxy nature (melting point ~54 °C) makes it useful for providing structure and texture in products ranging from creams to cleansers.

Emollient / Occlusive

Enhances skin feel by forming a light, protective lipid film.

Contributes to a smooth, non-greasy after-feel compared to longer-chain fatty acids.

Viscosity Modifier / Thickener

In solid or semi-solid systems (e.g., sticks, balms), it helps maintain firmness.

Can be combined with stearic or cetyl alcohol to adjust consistency.

Surfactant Precursor

Reacts with ethoxylates or sulfates to form myristic acid–derived surfactants (e.g., sodium myristate, PEG-150 myristate).

Provides foaming and cleansing properties when used as a soap or co-surfactant in cleansers and body washes.

Texture Enhancer in Anhydrous Systems

In lipsticks, eye shadows, and ointments, it contributes to slip and spreadability.

When blended with other fatty alcohols or waxes, it creates a stable matrix to hold pigments or active ingredients.

Appearance: White, waxy solid at room temperature.

Melting Point: ~50–54 °C.

Solubility Profile:

Insoluble in water.

Soluble in most oils, esters (e.g., isopropyl myristate), and common cosmetic solvents (e.g., ethanol).

pKa: ~4.8 (weak acid), but in finished products it typically exists in neutral or salt form.

Saponification Number: ~224–226 (useful when calculating soap blends).

Emulsion Creams / Lotions (Oil Phase):

0.5 %–3 % as an emollient or to boost viscosity.

Higher levels (~5 %–8 %) when targeting a firmer consistency (balm, stick).

Soaps and Body Washes:

10 %–20 % of total fatty acid blend when producing traditional cold-process or hot-process soap.

Provides a stable, creamy lather and hard bar structure.

Cleansing Bars / Syndet Bars:

2 %–5 % as part of a fatty acid blend (often with stearic and lauric acids) to balance hardness and lather.

Anhydrous Products (Lipsticks, Balms, Sticks):

5 %–15 % in combination with other waxes (e.g., beeswax, carnauba wax) and fatty alcohols (e.g., cetyl alcohol) for desired firmness and spread.

Surfactant Synthesis:

When forming sodium (or potassium) myristate soap: ~100 % of the fatty acid is neutralized with NaOH, typically yielding 8 %–12 % of bar weight in myristate soap bars.

For PEG-150 Myristate (polyethylene glycol ester): process myristic acid with PEG-150 to achieve 5 %–10 % of total surfactant blend (for nonionic surfactants).

Oil Phase Compatibility

Mixes readily with medium-chain triglycerides (MCT), isopropyl myristate, caprylic/capric triglyceride, and other fatty esters.

When formulating W/O (water-in-oil) systems, it can aid in stabilizing the internal water droplets by partially crystallizing at cooler temperatures.

Synergies with Other Lipids

In combination with stearic acid, cetyl alcohol, or behenic acid, it contributes to a solid lipid matrix.

Blends with natural butter (e.g., shea, cocoa) can soften the texture and improve spreadability at skin temperature.

Emulsifier Interactions

Does not function as an emulsifier alone; requires co-emulsifiers (e.g., glyceryl stearate, sorbitan monostearate).

Can be salified (e.g., sodium myristate) to act as a soap emulsifier in syndet bars.

pH and Ionic Strength

In emulsions, maintain pH above ~5 to keep free acid stable and prevent hydrolysis of adjacent esters.

If salified (soap form), watch for hardness or chalkiness at pH >10; adjust chelators (EDTA) to prevent calcium or magnesium salt precipitation.

| Mechanism | - |

| Appearance | - |

| Longevity | - |

| Strength | - |

| Storage | - |

| Shelf Life | - |

| Allergen(s) | - |

| Dosage (Range) | - |

| Recommended Dosage | - |

| Dosage (Per Day) | - |

| Recommended Dosage (Per Day) | - |

| Mix Method | - |

| Heat Resistance | - |

| Stable in pH range | - |

| Solubility | - |

| Product Types | - |

| INCI | - |