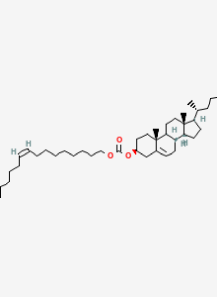

Cholesteryl Oleyl Carbonate

Cart

No products

No products

Cholesteryl Oleyl Carbonate is a cholesterol-derived mesogenic lipid (cholesteryl carbonate) widely used as a thermotropic cholesteric (chiral nematic) liquid-crystal former in oil-based systems.

In blends with higher-melting cholesteryl esters (for example Cholesteryl Nonanoate and Cholesteryl Benzoate), it helps tune phase transitions and broaden the working mesophase window, enabling temperature-dependent optical effects (iridescence) and structured, skin-feel enhancing oil phases.

Functionally, it behaves as a highly lipophilic, water-insoluble lipid that can contribute to emolliency, film feel, and oil-phase structuring when used alone or as part of a cholesteric liquid-crystal blend.

Product Description: Cholesteryl Oleyl Carbonate is typically the lower-melting, more flexible mesogen in a cholesteryl LC toolkit. In practical formulation work, it is commonly paired with higher-order cholesteryl esters to (1) shift phase behavior downward (closer to ambient/skin-relevant temperatures), (2) stabilize optical response over thermal cycling, and (3) improve robustness against slow crystallization drift.

How to use with Cholesteryl Nonanoate + Cholesteryl Benzoate (3-component tuning): Treat the trio as a tunable mesogen set where each component has a distinct job.

- Cholesteryl Oleyl Carbonate (this item): lower-melting, improves spreadability and helps pull transitions downward.

- Cholesteryl Nonanoate: waxy aliphatic C9 cholesteryl ester that helps build consistency and can broaden the working window.

- Cholesteryl Benzoate: rigid, high-melting aromatic cholesteryl ester that increases order and thermal stability (but raises crystallization risk if over-used or cooled too fast).

Screening ratios (w/w within the LC mesogen blend):

| Blend goal | COC | CN | CB | What to expect |

|---|---|---|---|---|

| Lower melt / softer feel | 50 | 35 | 15 | Easier processing; transitions shift downward; lower crystallization tendency |

| Balanced starting point | 40 | 40 | 20 | Good general screen for structure + stability; adjust oil phase to keep domains |

| More order / higher stability | 30 | 45 | 25 | Higher order; may need higher melt temp and slower cool; watch crystallization |

Usage: Oil-based serums, balms, lip products, make-up/oil gels, and emulsions where the ingredient is carried in the oil phase. Also used as a component of cholesteric liquid-crystal effect blends for temperature-dependent visual appearance.

Mixing method:

- Pre-melt into the oil phase with compatible esters/oils using heat (typ. 60–80°C; higher may be needed when CB is present) until uniform.

- Cool with controlled, gentle mixing; evaluate the final base after thermal cycling because appearance is thermal-history dependent.

- For optical effects, avoid high levels of strong solvents that keep the system fully molecularly dissolved; adjust oils/esters to keep a structured cholesteric domain after cooling.

Usage rate: 0.1–5%

For optical/iridescent cholesteric effects, a common starting point is ~0.2–3% of a cholesteric LC blend in the finished formula, then optimize for tack, stability, and appearance in your base. If using higher levels, verify tack and sensory because LC loading can increase tack in some systems.

Product characteristics: White to pale yellow waxy semi-solid; liquid-crystal forming lipid; slight characteristic odor.

Solubility: Insoluble in water. Soluble in many oils/esters and organic solvents (especially with heat); compatibility depends on the oil phase and may require co-mesogens for stable domain formation.

Storage: Store tightly closed, away from excessive heat and light. For best appearance stability, validate after repeated heat/cool cycles in the intended packaging.

| Mechanism | - |

| Appearance | - |

| Longevity | - |

| Strength | - |

| Storage | - |

| Shelf Life | - |

| Allergen(s) | - |

| Dosage (Range) | - |

| Recommended Dosage | - |

| Dosage (Per Day) | - |

| Recommended Dosage (Per Day) | - |

| Mix Method | - |

| Heat Resistance | - |

| Stable in pH range | - |

| Solubility | - |

| Product Types | - |

| INCI | - |