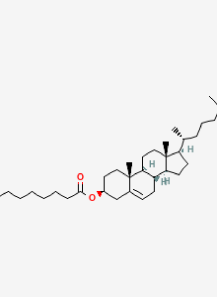

Cholesteryl Nonanoate

Cart

No products

No products

Cholesteryl Nonanoate (also known as cholesteryl pelargonate) is a cholesterol fatty-acid ester used primarily as a thermotropic cholesteric (chiral nematic) liquid-crystal former and secondarily as a lipidic emollient/structuring wax in oil phases.

It is highly lipophilic and essentially water-insoluble, so it partitions into the oil phase and can contribute to a richer, more structured feel when used in lipids and emulsions.

In cholesteric liquid-crystal blends, Cholesteryl Nonanoate often plays the role of a waxy, mid-to-higher melting mesogen that helps tune phase behavior, optical intensity, and stability when combined with lower-melting (more flexible) and higher-melting (more rigid) cholesteryl mesogens.

Product Description: Cholesteryl Nonanoate is used to build cholesteric LC domains that can produce temperature-dependent structural color (iridescence) when the formulation and processing conditions support domain formation. From an engineering perspective, it is best treated as a waxy, oil-phase structurant whose outcome depends on (1) the oil/ester selection, (2) the co-mesogen set, and (3) the thermal pathway used during manufacturing.

How to use with Cholesteryl Oleyl Carbonate + Cholesteryl Benzoate (3-component tuning):

- Cholesteryl Oleyl Carbonate: lower-melting/flexible mesogen (helps shift transitions downward and improve spreadability).

- Cholesteryl Nonanoate (this item): waxy aliphatic C9 cholesteryl ester that helps add consistency and can broaden the mesophase window.

- Cholesteryl Benzoate: rigid/high-melting mesogen that increases order and thermal stability (but can crystallize if over-used or cooled too fast).

Practical ratio set to screen (w/w within the LC mesogen blend):

- 50:35:15 (COC:CN:CB) for easier melting/softer feel.

- 40:40:20 as a balanced starting point.

- 30:45:25 when more order/thermal stability is needed (validate crystallization risk).

Binary anchor (COC:CN): A commonly cited tunable pair is around 36:64 (COC:CN) (w/w). If you want a more ordered/stable system, add a smaller CB fraction and re-optimize your oil phase.

Key formulation notes (LC systems):

- Solubilization can suppress structure: if the mesogens are fully dissolved by strong solvents or highly compatible oils, cholesteric domain formation and optical response can weaken.

- Thermal history matters: cooling rate and post-processing thermal cycling can shift appearance and stability.

- Blending is usually required: combining multiple cholesteryl mesogens can broaden the working window and reduce slow crystallization drift.

When used for sensorial/structuring (not optical effects), it functions as a lipophilic wax that can increase viscosity/consistency and contribute to a more cushiony, emollient feel.

Usage: Oil-based serums, balms, lip products, make-up/oil gels, and emulsions (oil phase). Also used as part of cholesteric LC blends where temperature-dependent iridescence/appearance is desired.

Mixing method:

- Pre-melt into the oil phase with heat (often 75–90°C; higher may be required when CB is included) until uniform.

- Cool under controlled, gentle mixing; validate appearance after thermal cycling in the final base and packaging.

- For optical effects, balance oils/esters and co-mesogens so the system forms a stable structured domain after cooling (not fully dissolved, not crystallized out).

Usage rate: 0.1–5%

For optical cholesteric effects, a common starting point is ~0.2–3% of a cholesteric LC blend in the finished formula, then optimize for tack, stability, and visual intensity.

Product characteristics: White to off-white waxy solid/powder; slight characteristic odor; oil-phase lipid.

Solubility: Insoluble in water. Soluble in oils and many organic solvents (especially with heat); may crystallize if overloaded or if the oil phase is insufficiently compatible.

Storage: Store tightly closed, dry, and away from excessive heat and light. Validate stability after repeated heat/cool cycles when used for optical appearance.

| Mechanism | - |

| Appearance | - |

| Longevity | - |

| Strength | - |

| Storage | - |

| Shelf Life | - |

| Allergen(s) | - |

| Dosage (Range) | - |

| Recommended Dosage | - |

| Dosage (Per Day) | - |

| Recommended Dosage (Per Day) | - |

| Mix Method | - |

| Heat Resistance | - |

| Stable in pH range | - |

| Solubility | - |

| Product Types | - |

| INCI | - |